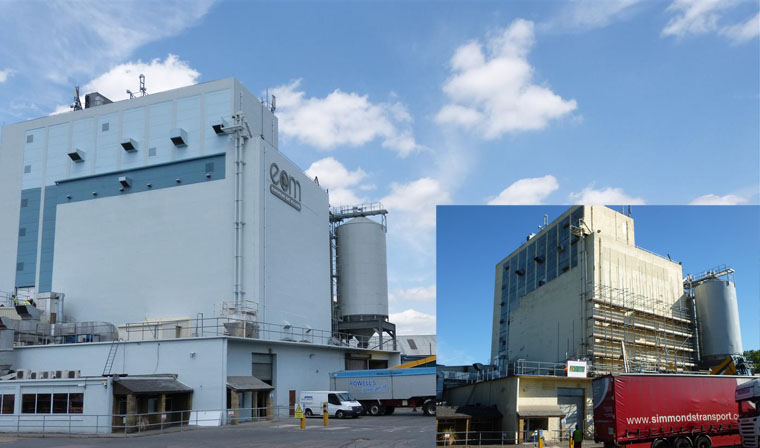

Concrete Repair and Decorative Anti-Carbonation Protection of Main Mill Building

Background

European Oat Millers is the second largest oat miller in the UK and Europe. The company produces a range of oat and cereal products that are used in a variety of retail lines found in most supermarkets and healthfood shops. The firm trades across three continents, with its distributor network reaching as far as the Middle East and Africa.

More than 120,000 tons of grain are processed across European Oat Millers’ two main sites, of which the primary site is the Bedford mill based in the heart of prime arable land in central England. The Bedford site houses a state-of-the-art manufacturing plant but the 1940’s thin walled concrete mill structure required significant refurbishment work as it was suffering from carbonation and chloride contamination. As the site is a busy manufacturing plant, it was important that there was only minimal disruption during the remedial works.

The Solution

We worked closely with Richard Jackson Engineering Consultants and Gunite (Eastern) Ltd to provide an effective solution. High levels of chlorides were identified so Cemprotec MCI® 2020, a surface applied migratory corrosion inhibitor, was used to provide further protection from the risk of corrosion. All exposed steel reinforcement was treated with Steel Reinforcement Protector 841 before areas of spalled and defective concrete were reinstated with Monomix, a structural grade, waterproof repair mortar that can be applied up to 80mm in a single application, even in overhead situations. Monolite, a low density repair mortar, was also used in areas where lightweight, cosmetic repairs were required. To prevent rapid drying out of the mortars, Curing Membrane WB was applied as a fine mist spray to the surface immediately after finishing.

The appearance of the external façade of the building needed to be enhanced and it was also necessary to provide overall anti-carbonation protection. Surface imperfections and voids were first filled with Monolevel FC fairing coat before overcoating with Monodex Smooth, a high build decorative coating which provides concrete substrates with outstanding protection against carbon dioxide diffusion. With a lifespan of at least 15 years before first maintenance, Monodex Smooth is CE marked in accordance with the demands of BS EN 1504, the pan European standard for concrete repair and it is ultra-fast drying, allowing two coat applications on the same day. Monodex Smooth has a water-based composition so it is ultra low odour and does not release any hazardous solvents, which was a critical consideration in this food manufacturing environment.

Client

Specifier

Richard Jackson Engineering Consultants