Oil & Gas Industry

Corrosion Prevention Strategies

For many years, Flexcrete has worked alongside some of the world’s leading oil and gas companies to develop and perfect our anti-corrosion coatings for pipelines. Our coatings are waterborne, low odour and non-hazardous, utilising thin film, polymer and epoxy modified cementitious coating technology to provide an effective long-term solution with many environmental and sustainability benefits.

Flexcrete’s cementitious coatings can be applied directly to ferrous metals without the need for primers and form a dense barrier designed to keep out the fuels for corrosion, achieving ultra-low permeability and diffusion resistance to oxygen and other gasses whilst preventing chloride ingress.

In addition, our Cemprotec E942 coating offers countless benefits over conventional pipeline coatings, including fusion bonded epoxies, three-layer polyolefins and liquid epoxies. What’s more, this technology is not limited to corrosion protection for steel pipelines.

Cementitious Technology

As Cemprotec E942 is cement-based, a homogeneous bond is achieved on concrete surfaces, making it the ideal choice for the protection of precast concrete sections which may otherwise be susceptible to damaging corrosion of the reinforcement or pre-stressing wires.

Contact Flexcrete TodayOil & Gas Industry Problems and Solutions

- Corrosion of Pipelines

- Exposure of Aggressive Chemicals

The Problem

Pipelines typically transport large quantities of oil or gas per day at high pressures, so require corrosion protection to ensure their original design life is achieved. It is important that any anti-corrosion products used are easy to apply in the field, often in very remote locations with minimal levels of surface preparation.

Pipelines typically transport large quantities of oil or gas per day at high pressures, so require corrosion protection to ensure their original design life is achieved. It is important that any anti-corrosion products used are easy to apply in the field, often in very remote locations with minimal levels of surface preparation.

The Solution

Cemprotec E942 is ideal as it is a stand-alone product and does not require a separate primer. With immediate passivation of the steel surface, it cures to form a tough and durable protective skin with good chemical resistance and excellent protection against mechanical damage. Cemprotec E942 also has a water-based, eco-friendly composition which is easy to apply and cures without the release of hazardous solvents or strong odour.

The Problem

The Solution

Our repair and protection products are water-based and cure without the release of hazardous solvents or strong odour, so they can be rapidly applied even in confined spaces whilst normal daily routines occur. Our cementitious coatings resist 10 bar water pressure and with our unique combination of epoxy and polymer technology in Cemprotec E942 and Cemprotec E-Floor, we offer products with enhanced chemical resistance.

Oil & Gas Industry Products

Find out more below about Flexcrete’s range of products for the oil and gas industry:

| Biodex Wash | A powerful surface treatment for neutralising active mould, fungal and bacterial growth prior to the application of Flexcrete products. |

|

| Bond-Prime | Single pack epoxy polymer primer to seal and consolidate substrates. |

|

| Cemprotec 2000-BJT | Self-adhesive butyl jointing tape designed to join sections of Cemprotec 2000-S together for waterproofing applications. |

|

| Cemprotec 2000-S | Elastomeric, waterproof reinforcing tape, giving a highly flexible seal over ‘live’ cracks. |

|

| Cemprotec E-Floor | Epoxy and cement modified polymer coating for protecting / waterproofing concrete floors. (2mm) |

|

| Cemprotec E-Floor HB | Epoxy and cement modified polymer coating for protecting / waterproofing concrete floors. (3-6mm) |

|

| Cemprotec EF Grit | Quartz aggregate for abrasion and skid resistance within E-Floor systems. |

|

| Cemprotec EF Primer | Single component sealer and primer for floors, prior to the application of the Cemprotec range. |

|

| Cemprotec E942 | Waterproofing and protection of concrete where enhanced chemical resistance is needed. Stand alone anti-corrosion coating for ferrous metal. |

|

| Cemprotec Elastic | Waterproofing and protection of concrete where further movement is expected. |

|

| Cemprotec Flex-Tape | Covering small, static cracks and joints. Covering larger cracks and joints which are subject to movement and spanning joints between dissimilar substrates. |

|

| Cemprotec GFM | An advanced glass fibre reinforcement matting system. |

|

| Cemprotec Levelling Coat | Self-levelling cementitious mortar for concrete floors prior to the application of Cemprotec E-Floor or Cemprotec E-Floor HB. |

|

| Cure-Seal WB | Water-based curing compound and clear sealer for Flexcrete Repair and Protection Systems. |

|

| Roofdex HB | High build, cold fluid applied liquid roofing system. |

|

Oil & Gas Industry Projects

Take a look below at some of Flexcrete’s latest projects in the oil and gas sector, or browse the project profile pages to find more.

Project Profile

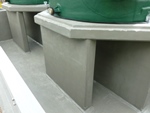

Project Location: Gorgon Project, Barrow Island, Australia

Flexcrete’s Cementitious Coating 851 was applied at one of the world’s largest natural gas projects, the Gorgon Project in Australia, for enhancement of concrete cover on reinforced concrete caissons.

Project Location: Swire Oilfield Services Tananger, Norway

Flexcrete’s Monodex Smooth weatherproof coating, was applied to 2,000m² of external walls to withstand harsh climatic conditions at an oil supply base, Norway.

Project Location: Tobago Airport aviation fuel supply line

Flexcrete’s anti-corrosion coating Cemprotec E942 was chosen for external corrosion protection on fuel pipeline at Tobago Airport.