Flooring surfaces in today’s railways are subject to heavy demands, and many were simply not designed to withstand the current footfall, impact and abrasion. Chris Lloyd demonstrates how innovative solutions for enhancing concrete floors in refurbishments and new builds can make all the difference to durability and safety.

There are many signs that concrete floor repairs are required within the UK rail industry. The substrate could have become uneven or smooth, making it a trip or slip hazard, or there could be water leaking into the space below. With many of the UK’s major rail stations now undergoing significant renovation work to ensure they meet modern structural standards, flooring is a critical refurbishment area and it is almost always important to ensure that disruption is minimised, as possession times will be limited and rail facilities will often remain fully operational during the work.

As well as undergoing refurbishment, many rail stations are currently being extended to accommodate more passengers and trains, so there is a significant amount of new build work taking place. This has its own challenges, not least of all ensuring that flooring surfaces meet the required design specification.

Concrete Floor Repairs In Maintenance Depots

It is not just rail stations that  need to be considered, but many other areas that are not visible to the public, such as maintenance depots or substations. One such example is Crown Point maintenance depot in Norwich which plays a pivotal role in maintaining a fleet of trains in East Anglia and on the inter-city line to London. Due to the extensive use of jacks to lift trains, the platforms had become badly worn and uneven.

need to be considered, but many other areas that are not visible to the public, such as maintenance depots or substations. One such example is Crown Point maintenance depot in Norwich which plays a pivotal role in maintaining a fleet of trains in East Anglia and on the inter-city line to London. Due to the extensive use of jacks to lift trains, the platforms had become badly worn and uneven.

Specified by Frankham Consultancy Group, Flexcrete products were used to reinstate and provide a durable, hard-wearing and chemically resistant finish. After planing the surface, Fastfill, a rapid setting Portland cement based mortar, was used to fill voids and repair the edges to the platforms. Fastfill sets in as little as 10 minutes at 20°C. and is designed for the repair of areas which cannot taken out of service for long periods, or in locations subjected to heavy wear such as platforms, decks, floors and footpaths.

Cemprotec E-Floor HB, a self-smoothing, water-based, epoxy and polymer modified cementitious flooring system, was applied at a thickness of 3-6mm with a 2mm top coat of regular Cemprotec E-Floor applied as a hard finishing layer. A silica sand was broadcast into the surface and sealed with Cemprotec Sandseal 75, a tough, clear polyurethane coating, to provide a slip resistant surface. The finished floor has excellent resistance to impact, abrasion, water, chloride ions and aggressive chemicals. The water-based composition of Flexcrete products is a vital consideration in the rail sector as it means they are low hazard, virtually odourless and cure without the release of hazardous solvents, so there is absolutely no disruption during application and no danger to the public.

Long Lasting Concrete Floor Repairs At Eaglescliffe

A more recent refurbishment project was undertaken at Eaglescliffe Railway Station in Stockton-on-Tees. Located on the Tees Valley Line at the junction with th e Northallerton-Eaglescliffe Line, it provides direct intercity services between London and Sunderland. Access onto the island platform is via a ramped footbridge but over the years, the passenger ramp had deteriorated significantly and there were large areas of concrete delamination and spalling. Remedial repairs had been carried out but these were showing signs of disbondment, thus a long-lasting repair and protection system was required, comprising both localised repairs and overall deck protection.

e Northallerton-Eaglescliffe Line, it provides direct intercity services between London and Sunderland. Access onto the island platform is via a ramped footbridge but over the years, the passenger ramp had deteriorated significantly and there were large areas of concrete delamination and spalling. Remedial repairs had been carried out but these were showing signs of disbondment, thus a long-lasting repair and protection system was required, comprising both localised repairs and overall deck protection.

Following thorough preparation, Fastfill structural repair mortar was used for localised repairs, including several deep repairs as it can be applied up to 300mm in a single application. The whole ramp area was then sealed with Cemprotec EF Primer before Cemprotec E-Floor HB was poured onto the primed surface and spread to the required thickness of 3-6mm.

Cemprotec E-Floor HB is CE marked in accordance with the demands of BS EN 1504, the pan European standard for concrete repair. To enhance the slip and abrasion resistance of the ramped area, Cemprotec EF Grit was immediately broadcast into the Cemprotec E-Floor HB and once the complete system was fully cured, Cemprotec Sandseal 75 clear coating was applied over the whole surface to effectively seal it. The result is an extremely hard-wearing, slip-resistant surface which will provide ultimate protection against foot traffic, wheelchair use, impact from heavy objects and attack from the elements.

A Practical Solution To Low Concrete Cover

Even when new concrete floors are installed, they may need further repair and protection. This was the case at West Ham London Underground, a busy transport hub in East London and one of three transport ‘hotspots’ feeding the London 2012 Games. As part of plans to strengthen the rail network and upgrade the power supply, a new substation was built at West Ham London Underground.

Even when new concrete floors are installed, they may need further repair and protection. This was the case at West Ham London Underground, a busy transport hub in East London and one of three transport ‘hotspots’ feeding the London 2012 Games. As part of plans to strengthen the rail network and upgrade the power supply, a new substation was built at West Ham London Underground.

The new substation is designed to help power the rail system and facilitate the introduction of new trains, increased capacity and improvements such as air conditioning and electronic signage. During construction of the substation, a new ground floor slab was installed totalling approximately 500m². However, low cover was detected on the concrete and an economical and practical solution was sought to enhance effective cover and ensure that the design life of the ground floor slab was achieved and extended.

Reinforced concrete must have an adequate thickness of concrete covering the steel reinforcement bars; the depth and quality of the cover concrete is vital, as the relatively thin layer of concrete protects the reinforcing steel from corrosion by maintaining an alkali environment and preventing the ingress of chloride ions and all the fuels for corrosion.

Cemprotec EF Primer was first used to prime and seal the substrate prior to the application of Cementitious Coating 851, a high performance, two component, waterborne cementitious modified polymer coating which provides reinstatement of effective cover on precast and in-situ reinforced concrete, enhancing durability to achieve specified design life. A 2mm application of Cementitious Coating 851 is equivalent to 100mm of good quality concrete. Being cement based, it chemically reacts with the substrate to form an integral part and has a design life equivalent to that of the concrete to which it is applied. 851 can be applied to green concrete, exhibits minimal hazard during application and is non-toxic when cured.

Cementitious Coating 851 is ideal for the structural waterproofing of concrete, resisting positive and negative pressure under a 100 metre head. It forms a hard, highly alkaline coating which not only protects concrete from the effects of aggressive acid gases, moisture and chlorides, but also has greatly enhanced chemical resistance. It is also compliant with LU Standard 1-085 ‘Fire Safety Performance of Materials’.

Concrete Waterproofing At Birmingham New Street

One of the UK’s biggest rail redevelopment projects is currently being undertaken at Birmingham New Street Station, the busiest station outside London and the busiest interchange in the UK with a train leaving the station every 37 seconds. Over 140,000 passengers use New Street every day, more than double the number it was originally designed to accommodate. The first section of the new station opened in April 2013 and once the project is fully complete in Summer 2015, there will be 36 new escalators and 15 new lifts.

One of the UK’s biggest rail redevelopment projects is currently being undertaken at Birmingham New Street Station, the busiest station outside London and the busiest interchange in the UK with a train leaving the station every 37 seconds. Over 140,000 passengers use New Street every day, more than double the number it was originally designed to accommodate. The first section of the new station opened in April 2013 and once the project is fully complete in Summer 2015, there will be 36 new escalators and 15 new lifts.

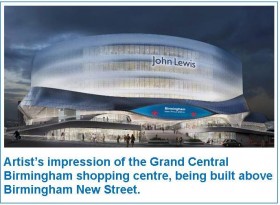

Situated above New Street Station is the Pallasades Shopping Centre which is undergoing a major transformation and will be known as Grand Central Birmingham when it opens in 2015. The centre will provide 200,000 sq ft of retail space for over 40 new premium fashion and lifestyle shops and more than 20 new concept cafes and restaurants. It will be anchored by the 250,000 sq ft John Lewis department store, the biggest outside London.

During the construction phase, it was necessary to waterproof the floor areas in the retail outlets to ensure there was no water damage to the underlying railway station and no inherent health and safety risks. Once again, a system based on Cemprotec E-Floor HB was specified for its ability to offer low permeability to water, even at 10 bar positive and negative pressure. It can be applied without risk of osmotic blistering to ‘green’ concrete, wet substrates or floors with no effective waterproofing membrane.

Conclusion

These case studies effectively demonstrate that we have worked with clients in the rail sector to develop innovative and durable flooring solutions which enable refurbishment and new build projects to be completed to programme and to budget, with no disruption to passengers and no health and safety risks during or post application.