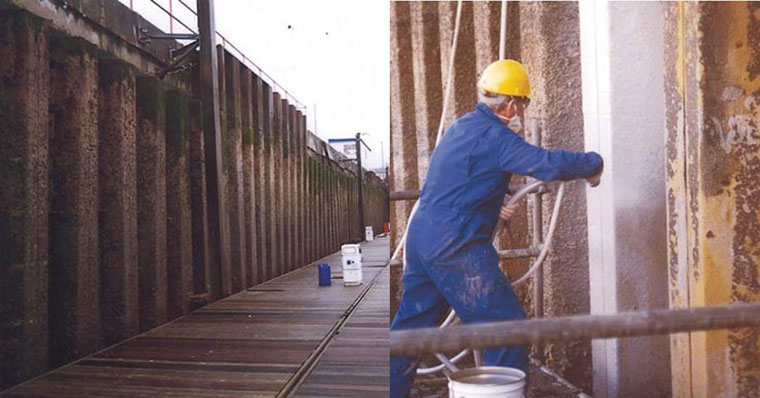

Corrosion protection of existing steel sheet piling suffering from ALWC.

Background

After 30 years’ exposure to salt spray and cyclical tidal immersion, the steel piled wall of the west quay at Brighton Marina was corroded to the extent that up to 60% of the section had been lost in some locations.

An innovative and environmentally friendly solution to this problem was required, and a Flexcrete specification appeared to be the most appealing of the options available.

The Solution

UHP water preparation of the steel removed all corrosion and other contamination, the 2,300 bar pressure leaving a clean surface suitable for coating. Thereafter, two coats of Cemprotec E942 were applied by spray techniques to give long term protection. The E942 does not rely on an initial priming system to gain adhesion, thus cutting down the application time. Also, residual surface dampness does not interfere with bond and tidal immersion is possible within 2 hours. An advanced epoxy and polymer modified cementitious coating, Cemprotec E942 forms a durable barrier to chlorides, oxygen and water, offering an excellent defence against corrosion for years to come.