Concrete deterioration exists on a global scale and can severely affect the durability of reinforced concrete structures. The primary causes of chemical attack on concrete include chloride ion penetration, sulphate attack and carbonation, but technical advances in cementitious coating technology have allowed extended service life solutions to be implemented.

A major cause of damage to reinforced concrete exposed to chlorides is corrosion of the steel reinforcement, especially for structures in marine, highway and other chloride-laden environments, including buildings in proximity to the coastline. Chloride ion penetration leads to the aggressive corrosion of steel reinforcement, even in alkaline concrete, causing cracking and spalling, and in the very worst cases structural failure.

Steel reinforcement is protected against corrosion by the inherent highly alkaline environment of the concrete created by the generation of calcium hydroxide from the cement hydration. This results in the formation of a passivating layer of ferric oxide on the embedded steel. As long as this surface film is maintained, the steel remains protected from corrosion.

However, when concrete structures are repeatedly exposed to airborne chlorides or salt spray, due to their minute size, chloride ions penetrate the pores of the concrete, eventually reaching the steel, breaking down this layer and causing corrosion. In the case of marine structures, corrosion most rapidly occurs in the splash zone where the intermittently wet and dry conditions exacerbate the penetration of chlorides and there is enough oxygen to facilitate the corrosion process. There is also sufficient moisture present to increase the electrical conductivity of the concrete, leading to an aggressive form of localised attack called pitting corrosion; this can potentially cause rapid loss of steel section and major cracking and spalling of concrete, thereby compromising structural integrity.

In tidal and submerged zones where the concrete is saturated in seawater and oxygen levels are limited, the pore structure is constantly filled with water. Nevertheless, in areas where there is low concrete cover, corrosion can still occur, causing a challenge for its reinstatement. The depth and quality of the cover concrete is vital, as the relatively thin layer of concrete protects the reinforcing steel from corrosion by maintaining an alkaline environment and preventing the ingress of chloride ions and the other fuels for corrosion. This is recognised in European Standards with EN 206 defining the concrete mix design and EN 10080 giving the requirements for cover.

Whilst marine structures are subject to constant exposure to chlorides, highway structures are similarly affected during the winter periods when de-icing salts are used. These readily dissolve in snow or rain water and the resultant highly concentrated salt solution or spray from vehicles can pose a threat to concrete structure within the vicinity of a highway with the potential for chloride ion ingress, exacerbated by repeated wetting and drying cycles.

As soon as low concrete cover has been identified, it is important to take swift action, otherwise the lack of protection to the re-bars will lead to premature de-passivation of the steel and subsequent corrosion. Inadequate concrete cover will not only speed up the damaging effects of carbonation but also allow even more rapid ingress of chlorides, moisture and oxygen. At worst, sections of concrete may need to be demolished, or partial recasting may need to be carried out, however both these options are very costly and often difficult to carry out

Water Facilities

In terms of reinforced concrete in waste water facilities, the most widely feared mechanism for the erosion of concrete in sewerage systems is bacterial in origin. Normal domestic sewage is slightly alkaline and does not contain sulphates in sufficient concentrations to attack concrete directly. The damage which occurs is due to sulphuric acid produced by certain bacteria as a result of changes occurring in sewage.

When conditions are such that oxygen in the sewage becomes depleted, anaerobic organisms, which do not use atmospheric oxygen, obtain their requirements for growth from salts. This also has the effect of reducing sulphates and other organic sulphur compounds in the sewage to form hydrogen sulphide.

Contrary to popular belief, the gas itself does not directly attack concrete, but it will readily dissolve in moisture particularly on the crown or soffit of sewers and on the walls above liquid level and is then oxidised to sulphuric acid by aerobic organisms of the Thiobacillusspecies. Research conducted in the USA indicates the concentration of sulphuric acid generated within sewerage systems peaks at circa 5%, which readily attacks normal concrete. There are various factors which determine the precise concentration but high temperatures are known to greatly encourage bacterial growth.

Soft Water Attack

Soft water is defined as water deficient in calcium and magnesium salts and can be a major problem in reservoirs storing high moorland or mountain water. Because of its pure nature, it effectively acts as a high performance solvent, dissolving the lime that is formed either as a by-product of the cement hydration process or is present in limestone aggregates to result in deterioration of the concrete.

Some soft waters also contain aggressive dissolved carbon dioxide which produces weak carbonic acid. Other organic acids naturally occur in soil and ground waters from rotting vegetation such as humic acid which originates from peat. These reduce the pH to below 5.0, thus making the water highly aggressive and undermining the integrity of concrete by weakening the matrix. With increased permeability, the concrete is vulnerable to advancing deterioration as the pore structure is opened to more acid ingress, ultimately resulting in breakdown of the substrate and failure of the structure to contain water.

There are cementitious coatings available that exhibit excellent resistance to attack from soft water. Key products incorporate pozzolanic materials and microsilica. Pozzolans react with the lime to form high levels of insoluble calcium silicate hydrates with very good chemical resistance. Microsilica effectively ‘mops up’ lime and affords enhanced resistance to chemical attack. Furthermore, the polymers incorporated into these materials form a protective film on the surfaces of the hydrates, subsequently enhancing the chemical resistance even further. Key products can also withstand immersed conditions without detrimental effect and have been specified for many contracts where water authorities have experienced specific problems with soft water attack.

As an example, cementitious coatings were used to repair over 30 reservoirs as part of the Northern Ireland Framework Rehabilitation Programme. Virtually all of the structures were suffering from soft water attack and in some cases, the attack was so severe that repair mortars were first used to reinstate the integrity of the substrate before a protective coating could be applied.

Carbonation Attack

Carbonation, which is the breakdown of the alkaline environment surrounding steel reinforcement, is another major problem in untreated concrete infrastructure exposed to atmosphere. Carbon dioxide migrates through cracks and pores in concrete, reducing the pH of the alkaline environment from 12-13 to around 9, inevitably leading to corrosion and concrete spalling. The carbonation of concrete is one of the main reasons for corrosion of reinforcement.

As detailed in an earlier paragraph, reinforced concrete buildings and other assets suffer from exposure to airborne chlorides in coastal environments. Without suitable protection from the elements, carbonation and chloride ingress combine to form a dangerous cocktail which, in addition to the effects of weathering, can soon impact on durability and the intended design life.

Protective Coating Technology

In the last 30 years, major technical advances have taken place in protective coating technology. Significant progress has been made by certain manufacturers of decorative anti-carbonation coatings to offer high levels of performance with a paint film thickness that would not have been possible even just 10 years ago. In the field of engineered protection for heavy duty applications, the latest cementitious coatings have allowed extended service life solutions to be implemented in conditions which are impractical for traditional alternatives.

The latest generation cementitious coatings will overcome many of the limitations of resin systems and can be applied to damp substrates without risk of osmotic blistering. Offering high resistance to wash-out, they withstand immersion as little as 60 minutes after placing. Their high build application and rapid cure makes them less susceptible to damage, especially during their early life. Furthermore, as water-based systems, the environmental credentials are attractive, posing minimal risk in application with all equipment being washed in water after use. Testing on structures suffering from carbonation which have been treated with such cementitious coatings shows that the concrete will realkalise and the depth of carbonation is reduced to afford further protection to the reinforcement, particularly in the presence of chlorides.

Cementitious coatings can be directly applied to reinforced concrete structures which are either approaching the end of their design life or which have suffered from premature degradation. These high performance coatings can also be used on new build structures as part of the original design or to provide a solution to non-conformance with specification. Where critical structures such as bridges are being built in onerous marine environments, consultants recognise the benefits of such coatings to help ensure the 120 year design life is achieved without the risk of costly future maintenance.

With regards to repair projects, defective concrete can be cut out and the steel reinforcement can be protected with a corrosion preventative, flexible coating to protect the steel prior to the application of concrete repair mortars and protective coatings.

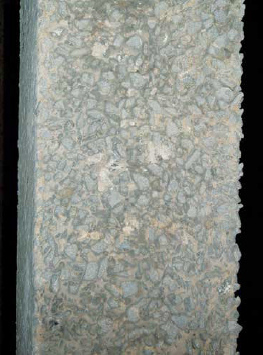

One product which is frequently specified on both existing and new structures to waterproof, reinstate cover and provide an effective barrier to chloride ingress is Intercrete 4841, formerly known as Flexcrete’s Cementitious Coating 851. Intercrete 4841 is a highly advanced, two component, waterborne cementitious modified polymer coating which was originally introduced in 1985, and it still remains one of the most effective products for providing structural protection against chloride attack. A 2mm coating of Intercrete 4841 is equivalent to 100mm of good quality concrete cover.

Independent testing carried out at the VINCI Construction Technology Centre in Bedfordshire has officially confirmed that Intercrete 4841 provides an effective barrier against chlorides lasting at least 30 years. In 1988, a 2mm thick film of Intercrete 4841 was applied to a concrete slice and sealed in a chloride ion diffusion cell, and 30 years (10,950 days) later it is still providing full protection. Continuous tests carried out in the VINCI Construction Technology Centre laboratory show that the barrier properties of Intercrete 4841 have remained the same throughout the test period, a testament to product’s consistent and long-lasting performance.

Many coating systems degrade over time when on test in the cell, and even products that initially perform well can subsequently blister, resulting in more chloride ions passing through the product. Intercrete 4841 has not shown any signs of deterioration despite being fully immersed in the chloride solution for 30 years. It would have taken 271 years for the product cell with the Intercrete 4841 to reach the same chloride concentration that the uncoated specimen reached in just 98 days.

Intercrete 4841 is widely specified on both existing and new structures in coastal environments, highways and the water and wastewater industry. It can also provide an alternative to the recasting or demolition of precast and in-situ reinforced concrete, reinforcing the substrate with the durability to achieve its specified design life.

Cases in Action

As part of a major £16 million upgrade of Eastbourne Wastewater Treatment Works, Intercrete concrete repair materials were chosen to refurbish an underground inlet chamber at the plant. Almost 140 tonnes of Intercrete 4801 was applied over a six month period by specialist asset maintenance contractor, Concrete Repairs Limited.

Dating back to 1997, Eastbourne Wastewater Treatment Works is located on the seafront at Langney Point in East Sussex. Serving a population of circa 140,000 people across the Eastbourne area, the vast majority of the works is located underground, beneath a fortress-style building. Up to 74 million litres of wastewater is pumped in and treated every day almost entirely out of sight.

The concrete repair work was carried out beneath ground level in extremely arduous conditions. The project involved the refurbishment of the underground inlet channel that receives wastewater flows, as the concrete had deteriorated due to attack from hydrogen sulphide (H2S) gas and sulphuric acid. The Intercrete application was carried out at night when flows were low.

An Intercrete system was devised for the project comprising a dry spray application of Intercrete 4801 repair mortar followed by a final coat of Intercrete 4840 cementitious coating. The system minimises environmental impact due to the fact that both products are water-based, ultra-low odour and solvent-free, making them safe to apply even whilst facilities are in operation.

Concrete Repairs Limited used hydro demolition methods before a dry spray application of Intercrete 4801 – a high strength, waterproof, class R4 mortar which exhibits extremely low rebound when applied either by dry or wet spray techniques for the structural repair, rendering and profiling of vertical, overhead and horizontal surfaces. Following the application of Intercrete 4801, Intercrete 4840 cementitious coating was applied. This combined Intercrete 4801/4840 system was chosen on the basis of the rapid curing properties and speed of reinstatement between application of the mortar and coating as there is no need for a skim coat due to the high quality finish of the mortar.

In another example, Doha Corniche is a waterfront promenade extending for 10km along Doha Bay in the capital city of Qatar, Doha. Formed following extensive dredging work carried out during the late 1970s and early 1980s which reshaped Doha’s coastline, the Corniche is now popular among walkers, bikers and joggers. Protection from high seas is provided by a concrete breakwater which suffers from erosion from wave action and chloride induced corrosion of the steel reinforcement.

When a new 500 metre precast concrete extension was constructed, the use of a chloride barrier was stipulated to extend the design life. Following consideration of a number of coating systems and intense testing, guided by Halcrow International and Partners (now Jacobs), the Ministry of Municipal Affairs and Agriculture (MMAA) specified a 2mm layer of Intercrete 4841. Applied in just two coats by spray equipment and bonding intimately to the concrete, Intercrete 4841 provided a durable waterproof layer which will not break down under the harsh direct sunlight.

In a further project illustrating the effectiveness of protective coatings to withstand sulphate and chloride contaminated ground conditions, over 400 tonnes of Intercrete 4841 was applied to the sub-structure reinforced concrete foundations to assure durability in aggressive ground conditions at the Q-Chem II Ethylene Derivatives Plant in Qatar. The installation of the protective coating was undertaken by Daewoo Engineering & Construction, the main contractor on this US$2bn project. The application was undertaken in compliance with a specification drawn up by Tecnimont S.p.A. of Italy on behalf of the joint venture owners, Qatar Petroleum and Conoco Phillips.

To download the full article please click on the link below: