It is evident that the application and performance limitations of some roofing materials adversely affect roof refurbishment and new build projects in South East Asia and other parts of the world. Graham James of Flexcrete Technologies explores the challenges that roofing coatings and systems face, and the challenges of the different applications.

The Challenges for Roof Coatings & Systems

The climate is a major factor, as prolonged exposure to ultra-violet light can lead to severe cracking and embrittlement in conventional roofing systems such as bituminous felt. Many traditional roofing materials also require the time-consuming and leak inducing processes of cutting, shaping and fixing. Premature failure can often occur at joints and upstands, making roofs prone to water penetration during heavy downpours. It goes without saying that leaking roofs can prove to be extremely costly and can cause severe disruption to daily routines within the underlying building.

Fire risks are also associated with heat-applied roofing systems requiring naked flame, hot air or hot gas and specifiers are coming under increasing pressure to utilise safer roofing materials and move away from old bitumen roofing technology. Some end clients have even gone so far as to ban the use of heat-applied roofing systems on their roofs altogether due to the fire risk they pose during application and the threat they impose to insured risk.

To eradicate these concerns, many end clients and roofing contractors around the world are moving towards the use of cold-applied liquid roofing systems. The concept of liquid roofing is relatively simple – it involves the protection of a roof structure by means of a cold fluid applied material that cures to produce a seamless, waterproof barrier. As there are no fixtures, seams, welds or joints, such roofing systems are easy to apply by brush, roller or airless spray, even over complex detail work, and are free from potentially weak areas where early failure might otherwise occur.

In roof refurbishment situations, the characteristic that appeals to many end users is that liquid roofing systems are applied directly over the existing substrate, so the failed material need not be stripped out and removed, which is not only expensive but often necessitates the closure of the building, as well as exposing it to further damage from the elements. Thus, work may be completed quietly and without disruption to activities within the underlying building, so any working routines can continue unhindered and corresponding downtime costs are eliminated. Importantly, liquid roofing systems pose absolutely no fire risks as they are cold applied, requiring no torches, burners or other heating equipment.

Roofdex HB Roof Coating

At Flexcrete Technologies Limited, there has been a great deal of interest in our latest cold fluid applied, high build, waterborne liquid roof coating Roofdex HB. Designed for the weatherproof protection of both flat and pitched roofs, it is especially suited for use in hot, humid climates due to its ability to reflect sunlight and withstand extreme temperature ranges without deterioration. It is highly elastomeric, able to tolerate thermal and structural movement, and vapour permeable, allowing the release of substrate moisture.

Roofdex HB maintains a wet edge even in direct sunlight so can be applied all year round. It effectively waterproofs structures for many years, whilst having the ability to reduce heat build-up and energy consumption. Roofdex HB is water-based with ultra-low VOC levels, which means it is environmentally friendly and releases no hazardous solvents or strong odour during application. Supplied as a single pack product, it requires no complex mixing on-site and achieves the highest possible fire rating of EXT.F.AA when tested to BS 476: Part 3: 2004.

Roofdex HB is suitable for both refurbishment and new build projects, with compatibility to a wide range of roofing substrates including asphalt, felt and cementitious roofs. A range of Roofdex HB systems can be created; it can be used unreinforced for the ultimate in cost-effective waterproofing, or it can be reinforced with various grades of glass fibre matting systems to provide long-term weatherproofing for up to 15 years. It is available in solar reflective white to reduce energy consumption, as well as reducing air conditioning costs. The colour range is extensive and special colours can be created or matched on request.

As environmental sustainability becomes more of a concern globally, green roofing is proving increasingly popular in South East Asia and Roofdex HB is an ideal waterproofing solution for these types of roofs. In essence, a green roof is a roof of a building or podium deck that is partially or completely covered with vegetation, such as grass, wild flowers and herbs, planted over a waterproofing membrane and often including additional layers such as drainage and irrigation systems.

Green roofs can offer savings on heating and cooling, provide effective insulation, reduce energy consumption, create a habitat for wildlife, help lower urban air temperatures and reduce Urban Heat Island (UHI) effect. Combatting UHI effect is a major reason for creating a green roof in South East Asia, as traditional building materials soak up the sun’s radiation and re-emit it as heat, making cities much hotter than surrounding areas.

Elevated temperatures also lead to the sea warming up, resulting in increased water evaporation and torrential downpours of rain. These flash floods are a major problem in concrete urban areas, as there is nowhere for the surface water to drain, other than drainage systems that cannot often cope with the sudden deluge of heavy rain. With green roofs, the roof is able to absorb the majority of the water, with the runoff taking days rather than minutes, thus relieving pressure on the drainage systems. Studies show that vegetated roofs are able to retain over 80% of rainfall compared to 27% with standard roof coverings. Green roofs are also energy efficient and air conditioning costs can be reduced by as much as 15% when they are installed.

Roofdex HB has recently be en applied to the rooftop of Tai Po Pumping Station on behalf of Hong Kong’s Water Supplies Department (WSD), as remedial work was required to replace a previously failed waterproofing system. A green roof was installed at the Pumping Station to help achieve environmental sustainability by reducing the rate and volume of stormwater runoff and minimising cooling loads on the underlying buildings in summer and heat loss in winter. The work was carried out for Kawada Industries, Inc. by Flexcrete’s Hong Kong based distributor, Technicient Engineering Company and specialist contractor Euro Pacific Waterproofing. Roofdex HB was applied in solar reflective white at Tai Po and tests have shown that Roofdex HB has outstanding resistance to weathering. Even after 22,0

en applied to the rooftop of Tai Po Pumping Station on behalf of Hong Kong’s Water Supplies Department (WSD), as remedial work was required to replace a previously failed waterproofing system. A green roof was installed at the Pumping Station to help achieve environmental sustainability by reducing the rate and volume of stormwater runoff and minimising cooling loads on the underlying buildings in summer and heat loss in winter. The work was carried out for Kawada Industries, Inc. by Flexcrete’s Hong Kong based distributor, Technicient Engineering Company and specialist contractor Euro Pacific Waterproofing. Roofdex HB was applied in solar reflective white at Tai Po and tests have shown that Roofdex HB has outstanding resistance to weathering. Even after 22,0 00 hours QUV-B testing, Roofdex HB has shown no signs of deterioration and it totally outperforms alternative roofing systems.

00 hours QUV-B testing, Roofdex HB has shown no signs of deterioration and it totally outperforms alternative roofing systems.

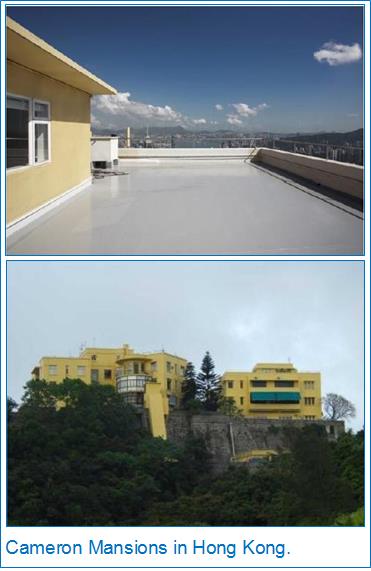

Technicient Engineering Company has also recently been involved in a prestigious Hong Kong project at Cameron Mansions on Magazine Gap Road, The Peak. Cameron Mansions is an exclusive residential address occupying a stunning hilltop position. Comprising a total of 18 luxury apartments arranged in four low rise blocks, Cameron Mansions commands impressive 360-degree panoramic views across the island of Hong Kong. The building is of historical importance as it stands on the foundations of the Japanese War Memorial which was built to honour those who died in the battle of Hong Kong. The War Memorial was demolished in 1947 and Cameron Mansions was constructed on the memorial’s foundations and established as private residences in 1951.

Due to the harsh climate, the existing roofing membrane at Cameron Mansions had deteriorated and an effective roof refurbishment solution was sought. The owners were also seeking to renovate the external walls with a high performance, weatherproof coating solution, matched to the distinctive yellow colour which makes the building stand out prominently in its local surroundings.

Roofdex HB was chosen for application to the roof areas due to its ability to provide total, seamless weatherproof protection for many years. It was specified in solar reflective light grey to reduce energy consumption by lowering heat gain from direct sunlight. So versatile is Roofdex HB that it was also chosen for application to the external walls at Cameron Mansions. Roofdex HB incorporates unique in-film protection, providing excellent resistance to algae and other biofilm attack, so it maintains a bright, clean appearance throughout its design life. A special yellow colour was created for the external walls to match the existing colour.

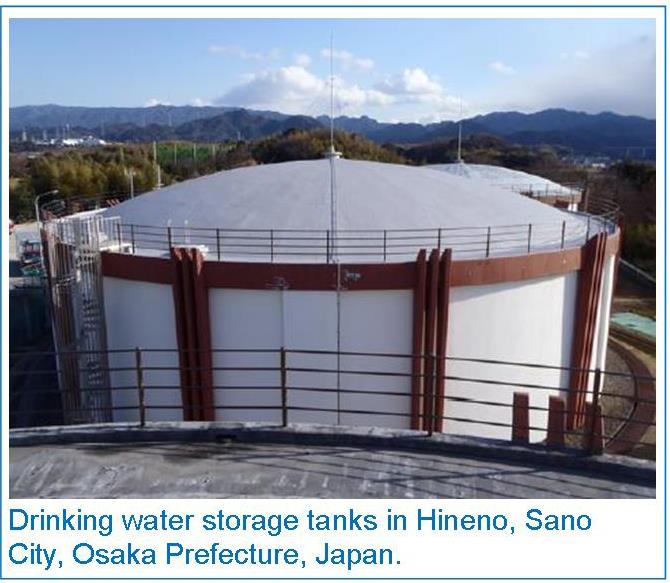

Flexcrete’s waterproofing systems are well proven in many countries around the region, and an interesting application can be found on the roofs of a series of drinking water storage tanks in Hineno, Sano City, Osaka Prefecture, Japan. Carried out for the Water Department of Sano City through Kitanihon Boshoku Co Ltd of Niigata City, the Flexcrete coating system was chosen on the basis of its excellent weatherproofing properties, rapid and simple application and elastomeric properties. An area totalling almost 1,000m2 was protected.

Flexcrete’s waterproofing systems are well proven in many countries around the region, and an interesting application can be found on the roofs of a series of drinking water storage tanks in Hineno, Sano City, Osaka Prefecture, Japan. Carried out for the Water Department of Sano City through Kitanihon Boshoku Co Ltd of Niigata City, the Flexcrete coating system was chosen on the basis of its excellent weatherproofing properties, rapid and simple application and elastomeric properties. An area totalling almost 1,000m2 was protected.

Tests have proven that Roofdex HB is resistant to rainfall during application and it can also withstand ponding soon after application. Ponding is ideal breeding ground for bacteria and Roofdex HB’s in-film protection provides effective anti-microbial protection against a wide range of micro-organisms. This makes Roofdex HB particularly suitable for use in hygiene sensitive areas, for example hospitals.

Roofdex HB is ideal for application to hospital roofs as it is completely solvent-free, environmentally friendly, odourless and inherently safe to use. When solvent-based roofing materials are used for hospital refurbishment projects, adjacent wards often have to close for the duration of the roof refurbishment work due to the odours and solvents released during application, which can cause massive disruption. With Roofdex HB however, daily routines can continue as normal and there is absolutely no need for any ward closures.

Originally part of the group that pioneered the fluid applied roofing market with a product called Decadex in the 1970’s, Flexcrete has been developing coating system technology for many years. Looking back, Decadex revolutionised the roofing industry as it was the world’s first water-based styrene butadiene rubber copolymer for the seamless refurbishment of leaking roofs. At the time, it represented a breakthrough in low odour, low hazard waterborne elastomers, signalling the way forward with cold fluid applied roofing membranes and the recent introduction of Roofdex HB.

Flexcrete Technologies Limited manufactures high performance fluid applied roofing systems, as well as a range of other products, including concrete repair mortars, fairing coats, waterproof cementitious coatings and decorative protective coatings. With its head office and manufacturing complex based in Leyland, North West England, Flexcrete products are available from stockholding distributors all around the UK. The company has a global presence through international agents and distributors in 65 countries worldwide with export sales accounting for over 50% of its business.